Applying Green Polyethylene and biodegradable resins widely

Sojitz Group is the largest foreign investor with voting right of Braskem S.A. the largest petrochemical company in the Central and South America. We are the exclusive authorized distributor of I’m Green Polyethylene (Green PE or GPE) in Asia and Oceania region for more than a decade.

GPE is made from 100% sugarcane waste molasses pure biomass derived plastic resin.

Braskem is the only one manufacturer of 100% biomass-based polyethylene in the world as of 2023.

Sojitz Group is now developing MEG one of major raw materials of PET resin from biomass together with Braskem through our JV, Sustenea.

We also distribute biodegradable resins globally.

Applications of such eco-friendly plastic resins are expanding day by day from substation of shopping bags or rubbish/garbage bags to product packaging, daily necessities, and industrial products. Awareness of “SDGs” urges society using eco-friendly materials much more. We are ready to support such requirements.

I'm Green Polyethylene

What is I'm Green Polyethylene?

Options for decarbonization

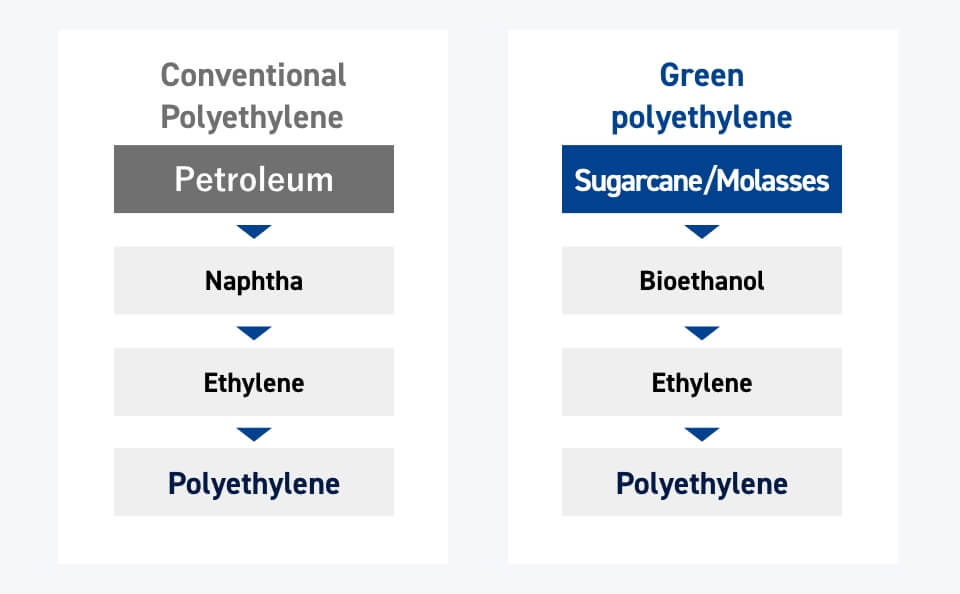

I'm Green Polyethylene is an eco-friendly polyethylene produced from sugarcane, manufactured worldwide solely by Braskem. This new material has exactly the same characteristics as conventional polyethylene, can be recycled, and facilitates the reduction of CO₂ emissions.

We serve as the official distributor of I'm Green Polyethylene to the Asia/Oceania region. Any product that can be manufactured with petroleum-based polyethylene can be produced entirely using I'm Green Polyethylene.

There are more than twenty grades of this material as well as a full lineup of HDPE, LDPE, and LLDPE materials. In general, we keep an inventory of every grade to support our clients' development of eco-friendly products.

Production Process of I'm Green Polyethylene

Reduction of CO₂ with I'm Green Polyethylene

*Compared to 1 ton of polyethylene during manufacturing

Reduction of 3.21 tons of CO₂ compared to petroleum-based PE

(Reduction in CO₂ emissions equivalent to the amount generated by burning 1,400 liters of gasoline)

Biodegradable Plastics

Providing eco-friendly materials that return to nature

Biodegradable plastic is a form of plastic that can be broken down by microorganisms at the molecular level, ultimately into carbon dioxide and water, thus returning to nature. As of 2021, the global production capacity for bioplastics (plastics derived from plant sources) has reached 2.42 million tons, of which 1.56 million tons, or 64%, were biodegradable. As production capacity continues to grow, we expect to see an increase by 2026 to 7.59 million tons, of which 5.31 tons, or approximately 70%, are likely to be biodegradable.

Principal Products

-

Polylactic Acid (PLA)

PLA is created through a process of polymerizing lactic acid derived from corn (maize) and sugarcane.

-

Polybutylene Adipate Terephthalate (PBAT)

PBAT is a biodegradable petroleum-derived plastic manufactured from the feedstocks 1,4-butanediol (BDO), terephthalic acid, and adipic acid.

-

Polybutylene Succinate (PBS)

A biodegradable petroleum-derived plastic manufactured from the feedstock succinic acid and 1,4-butanediol.(Plant-derived PBS containing bio-succinic acid produced from corn, sugarcane, etc., is also available. )

-

PHA

This is a marine-biodegradable resin produced by microorganisms from vegetable oil and other raw materials.

Contact

If you have a question or wish to consult with us,

please feel free to get in touch.